Expansion joints are a crucial component to an industrial piping system, allowing for movement caused by thermal expansion and equipment vibration. This expansion and vibration can be detrimental to the integrity of the machines and nearby equipment. This movement can also increase the risk of failure. Protecting your piping investment with proper installation of expansion joints is a reliable way to prevent failures and unnecessary down time.

Features and Benefits

- Versatile, reliable and economic solutions to your piping needs

- Delivers twice the movement allowances than standard arch construction

- Double reinforced construction provides longer joint life expectancy

- Hand wrapped custom built construction to allow for design variations, while still offering wide arch movement

- Suited for temperatures in excess of 350°F (176°C) depending upon service, reinforcement, and compound

- Exceptional directional movement absorption capabilities

- Available in a full range of elastomers to enable multi-purpose applications

- Construction provides woven polyester fabric and reinforced wire to create superior performance characteristics

- Standard and custom dimensions available

- Supports a piping system pressure range of 85 Psig to 225

- Standard and additional drilling available including Navy, ANSI, Metric and JIS

- Tube and cover materials available in: EPDM, Natural Rubber, Buna-N/Nitrile, Silicone, Neoprene, Gum Rubber, Hypalon, PTFE/FEP/TFE, Butyl, SBR/GRS/Buna-S, Viton®/Fluorel and Chlorobutyl

- Reinforcement Materials and Compatibility: Polyester, Fiberglass, Nomex, Nylon, Rayon and Kevlar®

- MOMTAJ Joints can be specially constructed for vacuum service and can be reinforced for higher pressure applications .

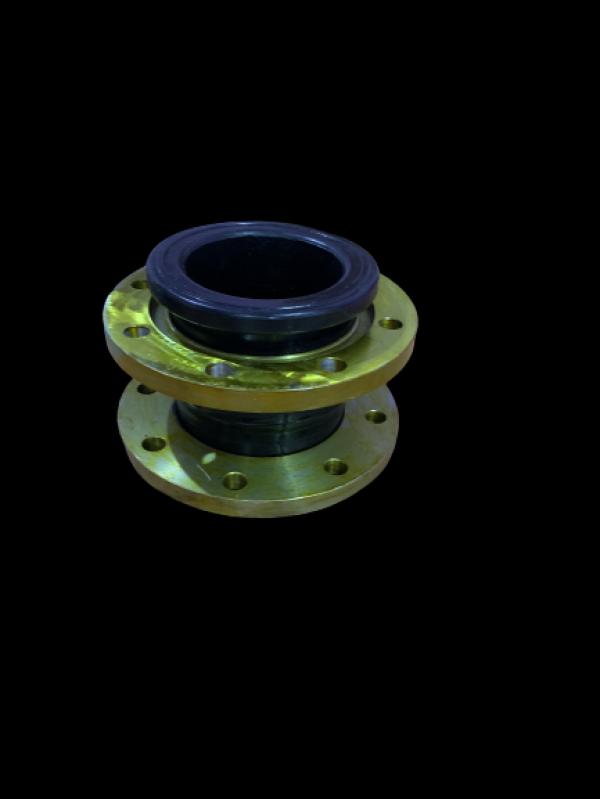

MOMTAJ Double Arch DuPont Kevlar®Reinforced Non-Metallic Expansion Joint

Features and Benefits

- Precision Laser-Cut Carbon Steel Flanges

- Powder-Coated Flanges for maximum durability

- Floating Flange Design for ease of installation

- Kevlar® wrapped steel ring encased in rubber flange

- Prevents the Tire-Cord from pulling away from the flange

- Provides Superior Sealing

- Available in non-standard face-to-face dimensions

- TEFLON® lining available

- Compensates for offset bolt holes and piping misalignment

Triple arch expansion joints are also available for greater movement and reduced spring rates. We can also manufacture Concentric and Eccentric Tapers and Offset styles. Sizes up to 144” can be constructed.

Standard control rods that install out-board of the mating flanges are standard. Integral tie rods attached to the floating flanges can also be supplied.

NOTE: Decrease of working pressure for constructions made of Kevlar® above 350°F.

Retorquing

After the initial installation, we recommend checking the torque of each bolt after 24 hours have elapsed or a temperature cycle or pressure cycle (hydrostatic test) has occurred. Any bolts falling below the recommended value should be retorqued. Values should only be exceeded by 10% increments when necessary to reseal. All torquing on the process system should be done when the system is ambient and cool.

Retourquing should be performed annually, especially if the system experiences elevated temperatures or extreme temperature swings.

MOMTAJ Available Materials and Temperature Ratings

In order to accommodate a wide array of temperatures, MOMTAJ is available in an assortment of elastomer and reinforcement combinations. Temperature allowances may range from 180°F to 400°F.

- Primary Elastomers

- Natural Rubber - 180°F

- Gum Rubber - 180°F

- Neoprene - 225°F

- Nitrile - 225°F

- EPDM - 250°F

- Hypalon - 250°F

- Chlorobutyl - 250°F

- Viton® - 400°F

- PTFE/FEP/TFE - 400°F

- Other Elastomers Available

- White FDA

- NSF

- Peroxide Cured

- 300°F rating available for EPDM and Chlorobutyl for Air Service at 50 PSI MAX